COMMON TYPES OF SHEET METAL

Different types of sheet metal materials

Sheet metal is super versatile and used in lots of industries. This guide breaks down different types, like hot rolled, cold rolled, aluminum, and stainless steel. It explains their unique features and where they're typically used. Our sheet metal racks are designed to hold all types of sheet metals.

Hot Rolled Steel

Hot rolled steel, one of the most common types of sheet metal, a product of a manufacturing process conducted at high temperatures, boasts a distinct surface finish characterized by its rough texture. Its key properties include excellent workability, making it a preferred choice for applications requiring moderate strength, commonly found in structural projects where malleability is crucial.

Cold Rolled Sheet Steel - Very Common Type of Sheet Metal

Cold rolled steel undergoes a process at lower temperatures, resulting in a smoother surface finish. Renowned for its high strength and good workability, cold-rolled steel is often employed in precision sheet metal fabrication, where dimensional accuracy and surface quality are paramount being one of most common types of sheet metal

Common Types of Sheet Metal - Aluminum Sheet Metal

Aluminum sheet metal stands out for its non-magnetic nature, lightweight structure, and corrosion resistance. This material is particularly favored for its excellent workability, with laser cutting being a prevalent technique in its fabrication due to its precision and efficiency. Industries ranging from aerospace to automotive frequently leverage aluminum's unique properties.

Stainless Steel Sheet Metal

Stainless steel, celebrated for its corrosion resistance and heat resistance, finds applications in environments with extreme temperatures and corrosive elements. Its non-magnetic nature and durability make it a preferred choice for fabricated parts subjected to challenging conditions.

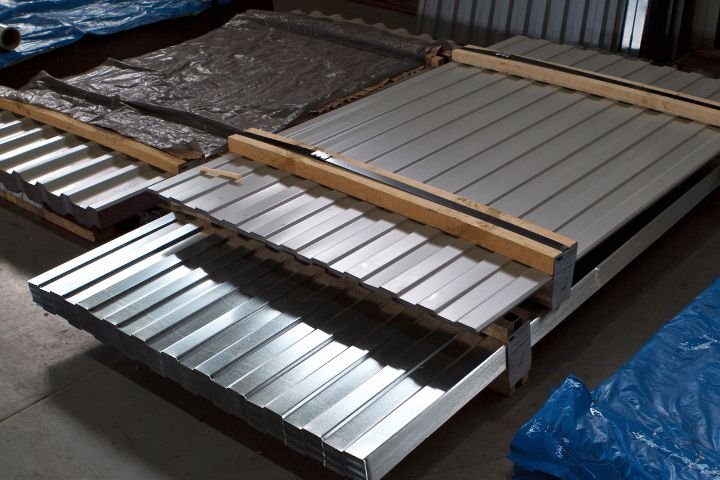

Galvanized Steel

Galvanized steel, featuring a protective zinc coating, offers enhanced corrosion resistance, preventing rust and making it a moderately priced option for various sheet metal parts. The galvanization process involves applying a layer of zinc, providing a robust shield against environmental factors.

Carbon Steel Metal material

Carbon steel, existing in various forms from low to medium to high carbon content, caters to diverse applications. Commonly found in different grades, carbon steel is utilized in manufacturing parts with varying hardness and strength levels, showcasing its adaptability across industries.

Alloy Sheet Metals

Alloy sheet metals, formed by combining multiple elements, offer a spectrum of properties catering to specific needs. Steel alloys, aluminum alloys, and nickel alloys are prominent examples, each presenting unique corrosion resistance and strength levels, making them suitable for various applications.

Copper Sheet Metal

Copper sheet metal is known for its excellent conductivity, corrosion resistance, and aesthetic appeal. Widely used in electrical applications, such as wiring and components, copper is valued for its ability to conduct electricity efficiently. Its corrosion resistance makes it suitable for outdoor applications, and its distinctive reddish-brown color adds an aesthetic touch to architectural projects.

Brass Sheet Metal

Brass, an alloy of copper and zinc, combines the conductivity of copper with the added benefits of increased strength and machinability. Brass sheet metal is utilized in decorative applications, musical instruments, and precision components where a balance of aesthetics and functionality is crucial.

Titanium Sheet Metal

Titanium sheet metal is prized for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. Aerospace and medical industries extensively use titanium for its ability to withstand extreme conditions and compatibility with the human body. Its lightweight nature makes it a preferred choice for aircraft components.

Zinc Sheet Metal

Zinc sheet metal is recognized for its protective properties, often used as a coating on steel (galvanization) or as a standalone material in roofing applications. It provides excellent corrosion resistance and is known for its self-healing properties, forming a protective patina over time.

Nickel Sheet Metal

Nickel alloys, including materials like Inconel and Monel, offer high-temperature resistance, corrosion resistance, and excellent mechanical properties. These alloys find applications in extreme environments such as aerospace, chemical processing, and marine engineering, where durability and reliability are paramount.

Lead Sheet Metal

Lead sheet metal is valued for its density and ability to block radiation, making it suitable for applications in the medical field, nuclear facilities, and as a radiation shield. Its malleability allows it to be easily shaped, making it versatile for various specialized uses.

Magnesium Sheet Metal

Magnesium sheet metal is known for its low density, making it one of the lightest structural materials. Commonly used in industries where weight is a critical factor, such as automotive and aerospace, magnesium alloys provide strength and durability while significantly reducing overall component weight.

High-Performance Alloys

Beyond standard alloy sheet metals, there are high-performance alloys designed for specific applications. Examples include Hastelloy, known for its corrosion resistance in aggressive chemical environments, and Maraging steel, prized for its high-strength properties and toughness.

Innovations in Composite Sheet Metals

Advancements in materials science have led to the development of composite sheet metals, combining different materials to achieve unique properties. For instance, fiber-reinforced composites with a metal matrix offer a blend of strength, lightweight construction, and corrosion resistance, suitable for advanced aerospace and automotive applications.

Environmental Considerations

With growing awareness of environmental sustainability, eco-friendly sheet metal options are gaining prominence. Recycled steel and aluminum, for example, contribute to reducing the environmental impact of metal production, providing sustainable alternatives without compromising on performance.

Sheet Metal Fabrication is Perfect for all Common Types of Sheet Metal

Sheet metal fabrication involves processes such as cutting, bending, and assembling to create manufactured parts. Its significance lies in the excellent resistance, weldability, and material selection, making it indispensable across industries for crafting components with precise specifications.

Corrosion Resistance and Material Selection

Corrosion resistance is a critical factor in material selection, particularly for structural and fabricated parts. Materials like stainless steel and galvanized steel offer varying degrees of corrosion resistance, ensuring longevity and durability in diverse applications.

Material Selection for Structural Applications:

Choosing the right sheet metal for structural applications involves considering factors such as tensile strength, thermal conductivity, and surface finishes. High-strength alloys and specific steel grades designed for structural purposes exemplify the meticulous process of material selection for optimal performance.

Navigating the vast landscape of sheet metal types unveils a world of possibilities for diverse applications. Whether it's hot rolled steel providing malleability for structural projects or aluminum offering lightweight efficiency, each sheet metal type possesses distinct characteristics that cater to specific requirements. By understanding the nuances of these materials, one can make informed decisions in material selection for their next project, ensuring efficiency, durability, and precision in fabrication processes.